Initiatives for the environment

Policy for environmental initiatives

We have set our basic policy for the environment to carry out environment-conscious business activities.

This policy is shared by all group companies, and all group companies join hands to promote environmental initiatives.

Basic policy for the environment

1Thoroughgoing observance of laws and regulations

We shall observe international environmental regulations and environmental laws and regulations of Japan and each municipality.

2Reduction of environmental burdens

When conducting business activities, we shall give consideration to environmental burdens and the impact on ecosystems.

3Promotion of environmentally friendly products and procurement

We shall promote the effective utilization of resources and energy, by promoting green purchase, adopting energy-saving technologies, developing technologies for saving and recycling resources, reducing waste, and so on.

4Initiatives for realizing an affluent social environment

We shall strive to offer products, services, and social systems that would conserve and improve the environment.

Environmental management

Environmental management structure

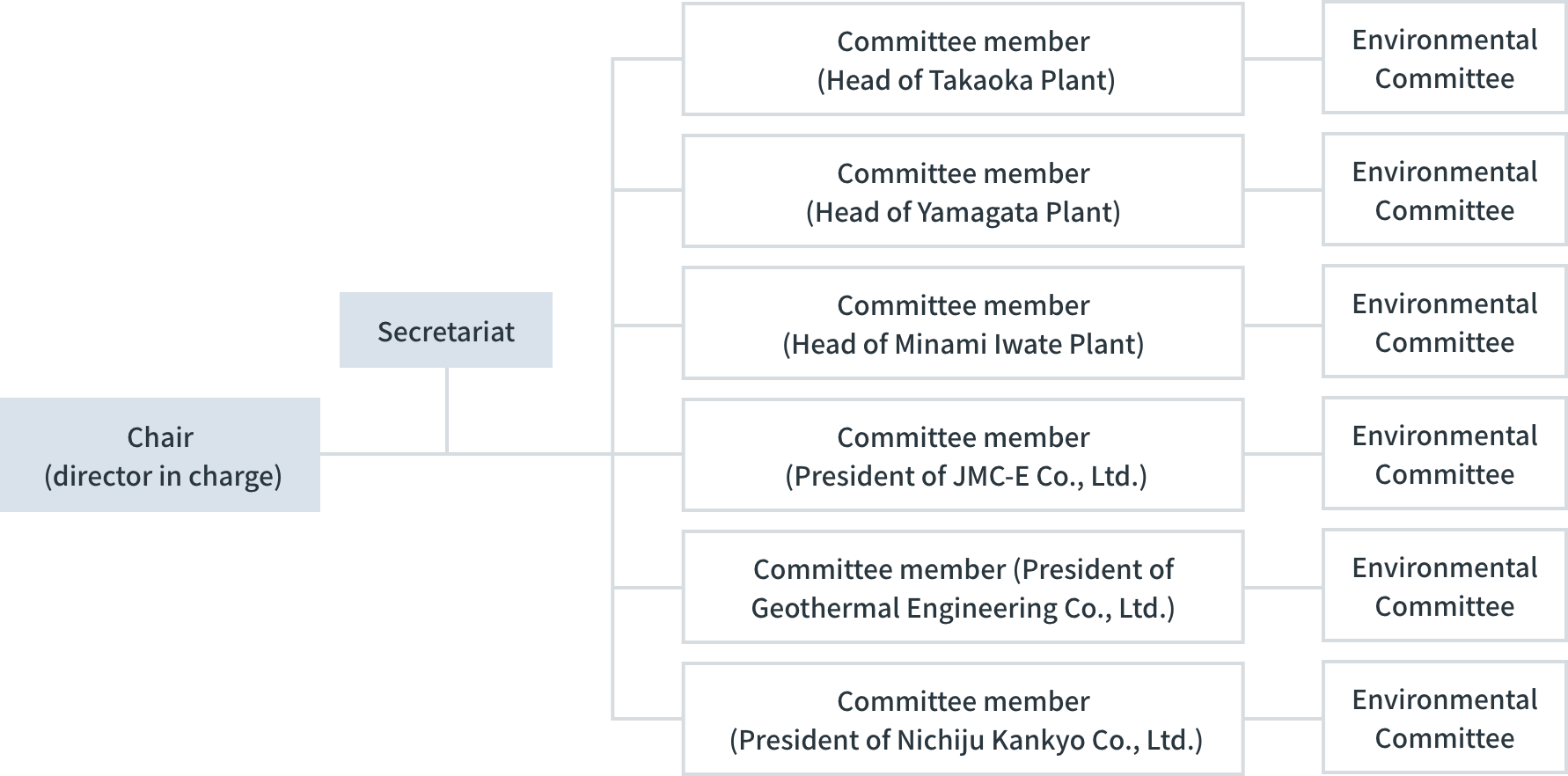

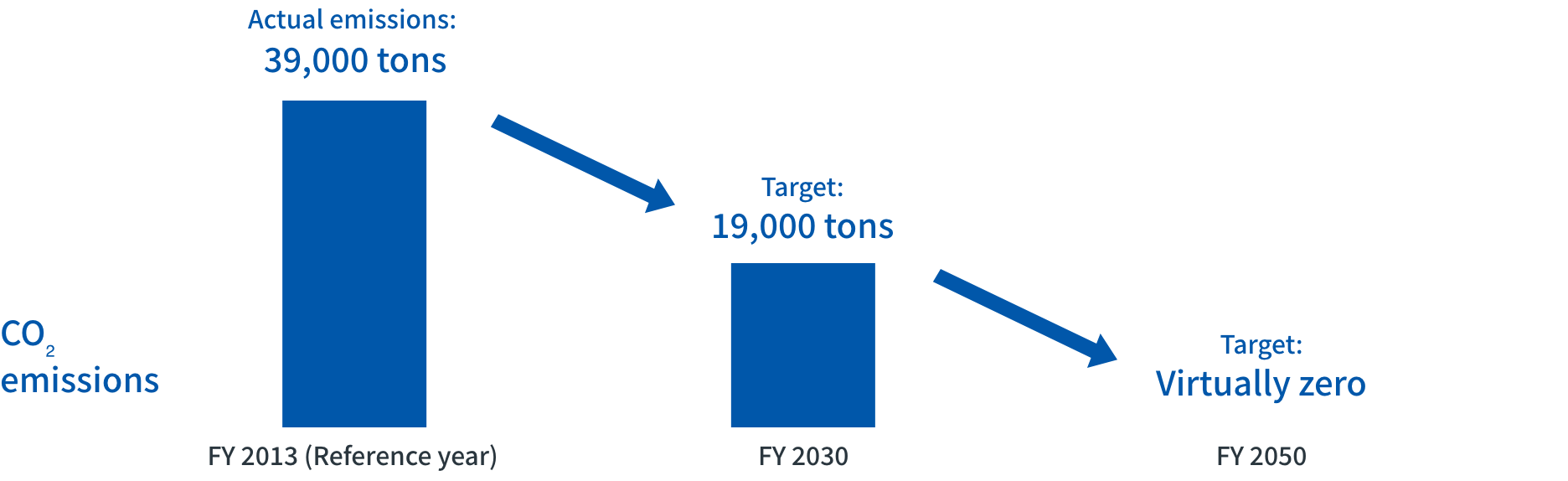

The JMC Group established a “JMC Group Environmental Committee” as a group-wide committee, which is chaired by the director in charge. The committee members include the head of each plant and the president of each group company. The committee designs environmental strategies, monitors and evaluates the progress of each measure, provides information on laws and regulations related to the environment, and discusses how to deal with them. In addition, each of plants and group companies has an environmental committee, to carry out the PDCA cycle for implementing the measures determined at the group-wide committee.

JMC Group Environmental Committee

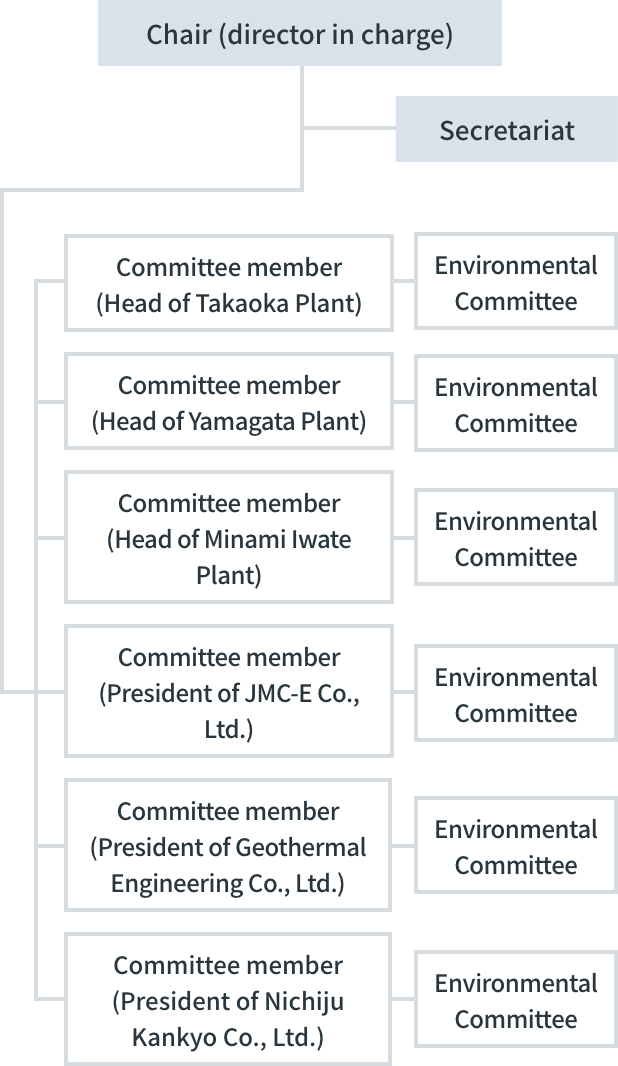

Environmental goals

In JMC, the group-wide environment committee adjusts the environmental goals for each fiscal year based on the results in the previous fiscal year, to reduce environmental burdens. In addition, we recognize the response to climate change as an important issue, and set a medium-term goal for reducing CO2 emissions as an initiative for carbon neutrality.

(See “Important issue: Response to climate change.”)

Situation of attainment of the environmental goals for FY 2023

Situation of energy consumption

/Sustainability data

Situation of the amount of industrial waste/Sustainability data

Environmental management system

JMC obtained the certification of the international standard ISO14001 for the environmental management system, and operates the system that complies with its requirements.

Situation of acquisition of the ISO14001 certificate/Sustainability data

Environmental education

In order to improve employees’ ability to conserve the environment, each environmental committee offers environmental education. In addition, we encourage employees to obtain qualifications and support them, so that they will follow laws and hone their skills.

Number of employees who have obtained environmental qualifications

/Sustainability data

Observance of laws and regulations related to the environment

Each plant of JMC makes efforts to observe environmental laws and regulations of Japan and each region. In FY2023, we had no violation or adverse disposition regarding environmental laws and regulations. We will continue to make efforts in complying with laws and regulations thoroughly.

Important issue: Response to climate change

JMC recognizes the response to climate change as an important issue, and engages in measures for realizing carbon neutrality through business activities.

Furthermore, we contribute to the reduction of CO2 emissions in the entire society through our products.

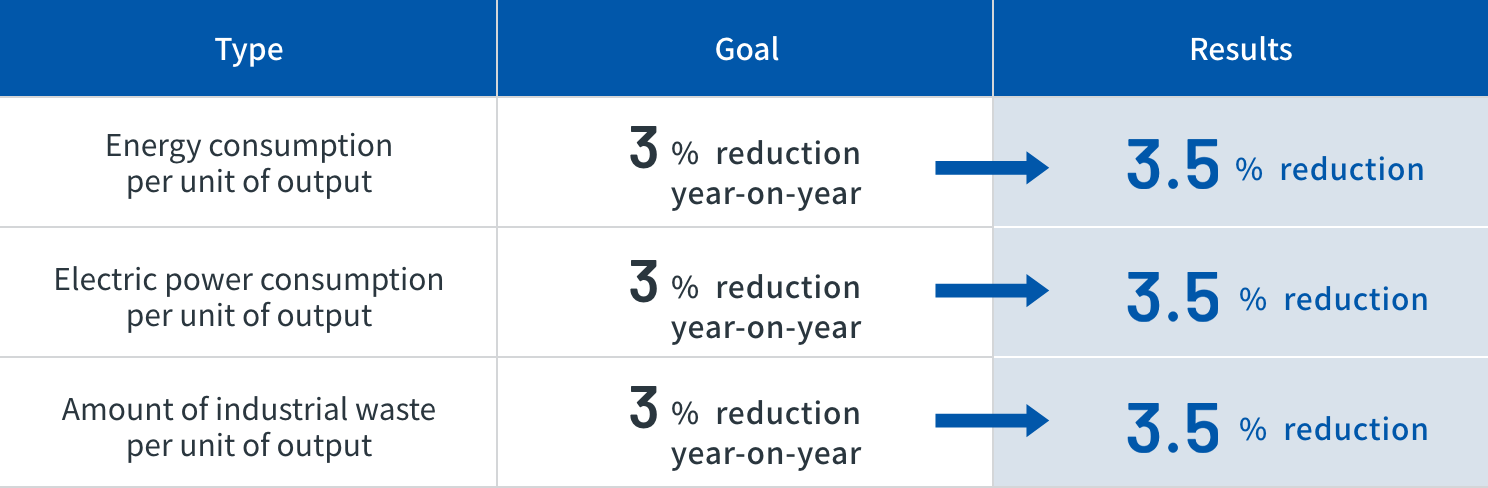

Medium/long-term goals for carbon neutrality

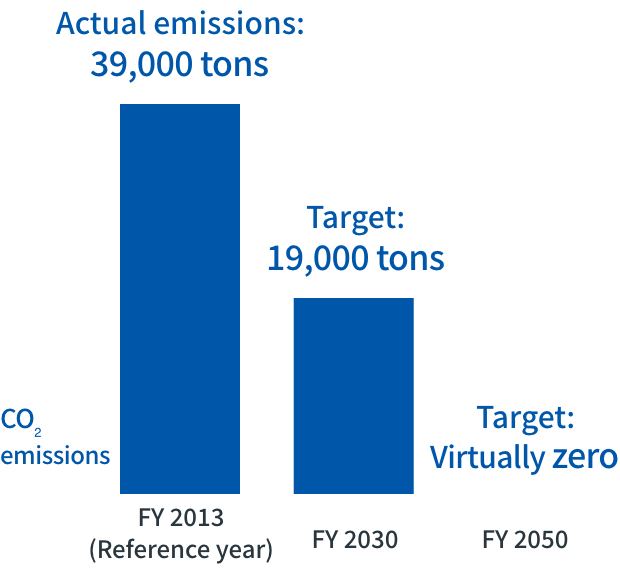

JMC set medium/long-term goals for reducing CO2 emissions in 2022, with the aim of achieving carbon neutrality. We aim to reduce real CO2 emissions and achieve virtually zero emissions in 2050, by pursuing energy saving in our business activities and purchasing electric power generated from renewable energy. In addition, we will contribute to the reduction of CO2 emissions in the entire society through the businesses of production of electrode materials for rechargeable batteries used for EVs and renewable energy, including geothermal power.

Using the CO2 emissions in FY 2013 as a reference value, we aim to reduce CO2 emissions by 50% by FY 2030 and achieve virtually zero emissions by FY 2050.

Situation of CO2 emissions

/Sustainability data

Energy saving in business activities

We sum up the energy consumption amounts of all group companies, conduct year-on-year comparison, check the status of usage, deal with the maximum demand for electricity, and implement concrete measures for saving energy, such as the update of archaic equipment, the installation of highly efficient machines, and the replacement of conventional lamps with LED lamps.

Thanks to these activities, our company was selected as an excellent business operator in energy saving (Class S) in “Evaluation System for Classifying Business Operators (for submissions in FY 2023)” of the Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry. In order to be evaluated as Class S in this evaluation system, it is necessary to reduce energy consumption per unit of output by 1% or more per year for 6 years. JMC has been evaluated as Class S for 5 consecutive years since FY 2018.

Situation of energy consumption

/Sustainability data

Utilization of renewable energy

JMC contributes to the reduction of CO2 emissions, by purchasing electric power derived from renewable energy. In April 2022, the Oguni Factory started partially purchasing and using electric power derived from renewable energy, reducing the CO2 emissions of the entire JMC group significantly.

Contribution through products and services

Special ferrosilicon

The “special ferrosilicon” produced by the joint-venture company in Brazil is a base material for manufacturing magnetic steel sheets, which are used for the motors of EVs, the transformers of power grids, etc. While response to climate change is intensifying globally, the “special ferrosilicon” provided by JMC indirectly contributes to measures against climate change through the distribution of EVs. In addition, the factory of the joint-venture company uses charcoal produced from eucalyptus trees in the forest owned by the company, to reduce GHG emissions in production activities.

Hydrogen storage alloy and negative-electrode silicon materials

Hydrogen storage alloy, whose manufacturing started on a full-scale basis in 1992, is a negative-electrode material for nickel-hydrogen batteries used for the batteries of EVs. We also supply negative-electrode silicon materials for lithium-ion batteries, which have been distributed further as batteries for EVs, contributing to the distribution of EVs.

In addition, hydrogen storage alloy can absorb and emit hydrogen by utilizing pressure and temperature in a relatively easy manner. By utilizing this characteristic, we can convert surplus power from renewable energy into hydrogen energy and then extract hydrogen energy and convert it into electricity or heat when necessary, to promote the use of renewable energy.

Hydrogen storage alloy

Hydrogen storage alloy Negative-electrode silicon materials

Negative-electrode silicon materials

Services related to geothermal/solar power generation

In 1966, JMC constructed the Matsukawa Geothermal Power Plant as Japan’s first geothermal power plant in Iwate Prefecture, and succeeded in generating geothermal power on a commercial scale. As a pioneer in geothermal power generation, our company has conducted surveys on the use of geothermal energy, the heat of hot springs, etc. and developed systems for harnessing them inside and outside Japan. In recent years, the Matsuohachimantai Geothermal Power Plant of Iwate Geothermal Power Co., Ltd., which was established in cooperation with affiliated companies and business partners, started operation in 2019. By supplying electric power to local consumers, we have achieved local generation for local consumption.

In addition to geothermal power, we constructed the Date Solar Power Plant in Date City, Fukushima Prefecture in October 2013, and started operating mega-solar power generation. This facility can generate up to 1.59 MW of power, and supplies 1.92 million kWh of power per year (equivalent to the power for about 500 ordinary households).

Matsuohachimantai Geothermal Power Plant

Matsuohachimantai Geothermal Power Plant Date Solar Power Plant

Date Solar Power Plant

Promotion of recycling of resources

In order to realize a recycling society, JMC proactively conducts measures utilizing the technology for recycling resources.

In addition, we strive to utilize resources effectively in our daily business activities.

Measures for products and services

Recycling of rare metals

Regarding the used large-capacity batteries of EVs, including hybrid vehicles, which were distributed on a full-scale basis in the 2000s, JMC worked on the development of technologies for recycling them earlier than other companies. In 2013, we started the recycling business for recovering rare earth from used nickel-hydrogen batteries.

In addition, we started recycling lithium-ion batteries, which have been recently adopted for EVs as alternatives to nickel-hydrogen batteries. We produce alloys (raw materials for recycling) with almost no external energy, and proceed with the development and practical application of technologies for recycling resources, such as rare metal and lithium.

Measures in business activities

JMC works on the reduction of industrial waste, with the basic policy of 3Rs (reduce, reuse, and recycle).

Situation of the amount of industrial waste/Sustainability data

Other measures for reducing environmental burdens

JMC conducts environment-conscious business activities, under the basic policy for the environment.

Prevention of air pollution

Takaoka Plant and Yamagata Plant, which are our production bases, measure discharged gases at a predetermined frequency in accordance with the Air Pollution Control Law.

Prevention of water pollution

Takaoka Plant and Yamagata Plant, which are our production bases, measure water quality in accordance with the Water Pollution Prevention Act. Additionally, we hold drills for responding to emergency situations while assuming leak accidents, and revise written procedures for dealing with accidents.

Appropriate management of chemical substances

JMC enhanced the management of substances of concern, such as chemical substances, and works on the reduction of discharge of harmful substances. We manage chemical substances and submit notifications in accordance with the “Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement (PRTR Act)” and the “Act on the Regulation of Manufacture and Evaluation of Chemical Substances.”

Management of polychlorinated biphenyls (PCBs)

We had been treating waste including low and high concentrations of PCBs as planned, in accordance with the “Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes.” We have completed all kinds of treatments process in FY 2023.

Handling, storage, and management of hazardous materials

Plants handling hazardous materials closely communicate with relevant fire departments, and conduct the following measures in order to prevent accidents, such as fires and leakage, and secure the safety of employees.

- Thoroughgoing indication of hazardous materials

- Placing fire extinguishers and protective equipment

- Safety education on hazardous materials

- To encourage employees to obtain the qualification as “a dangerous object handler” for raising and enhancing the awareness of hazardous materials