Cast steel

To meet Meeting diverse requests for production of cast steel

We have been operating the cast steel business for over 60 years since the cast steel division of the Takaoka Plant was established in 1960. Many metal products in the world have been produced through casting. Our company has accumulated plentiful experiences of producing cast steel for many years. In particular, we have an abundant track record of producing abrasion-resistant steel and utilizing our experiences to produce crushing machine blades. We meet a variety of requirements from clients with our advanced technologies.

Our product lineup

What are cast metal and cast steel?

A processing method in which molten metal is poured into a man-made mold and congealed is called “casting,” and “cast metal” means metal molded through casting. “Cast steel” is one kind of cast metal. In addition to cast steel, cast metal includes “cast iron,” “copper alloy,” and “light alloy.” “Cast steel” is excellent in toughness and ductility, because graphite does not deposit. In addition, as its characteristic, by adding alloy to steel with a carbon content of 2.14% or lower, it is possible to produce an excellent material that is resistant to abrasion, corrosion, and heat.

Heat treatment technology

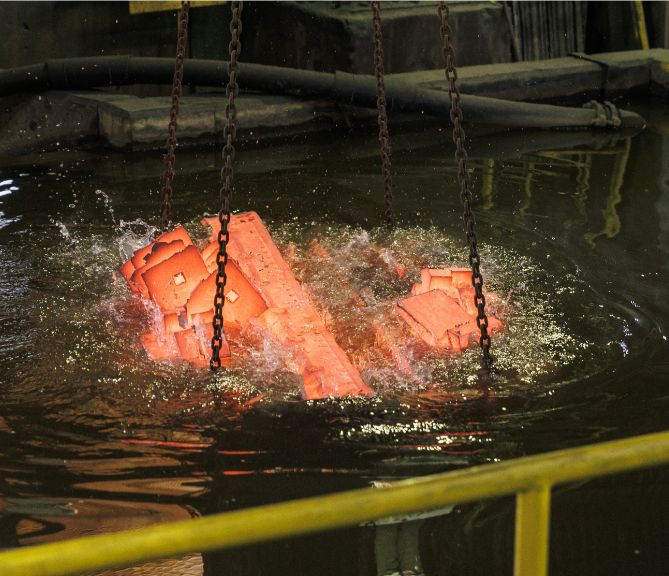

In general, cast steel undergoes heat treatment. In most cases, only heat-resistant cast steel can be used as it is.

Heat treatment means heating an object to “redden it” or “cooling” an object. Cooling can be classified into “quenching,” “tempering,” “annealing,” and “normalizing.”

Cast steel manufacturing facility

Takaoka Plant

Our cast steel is manufactured at the Takaoka Plant.

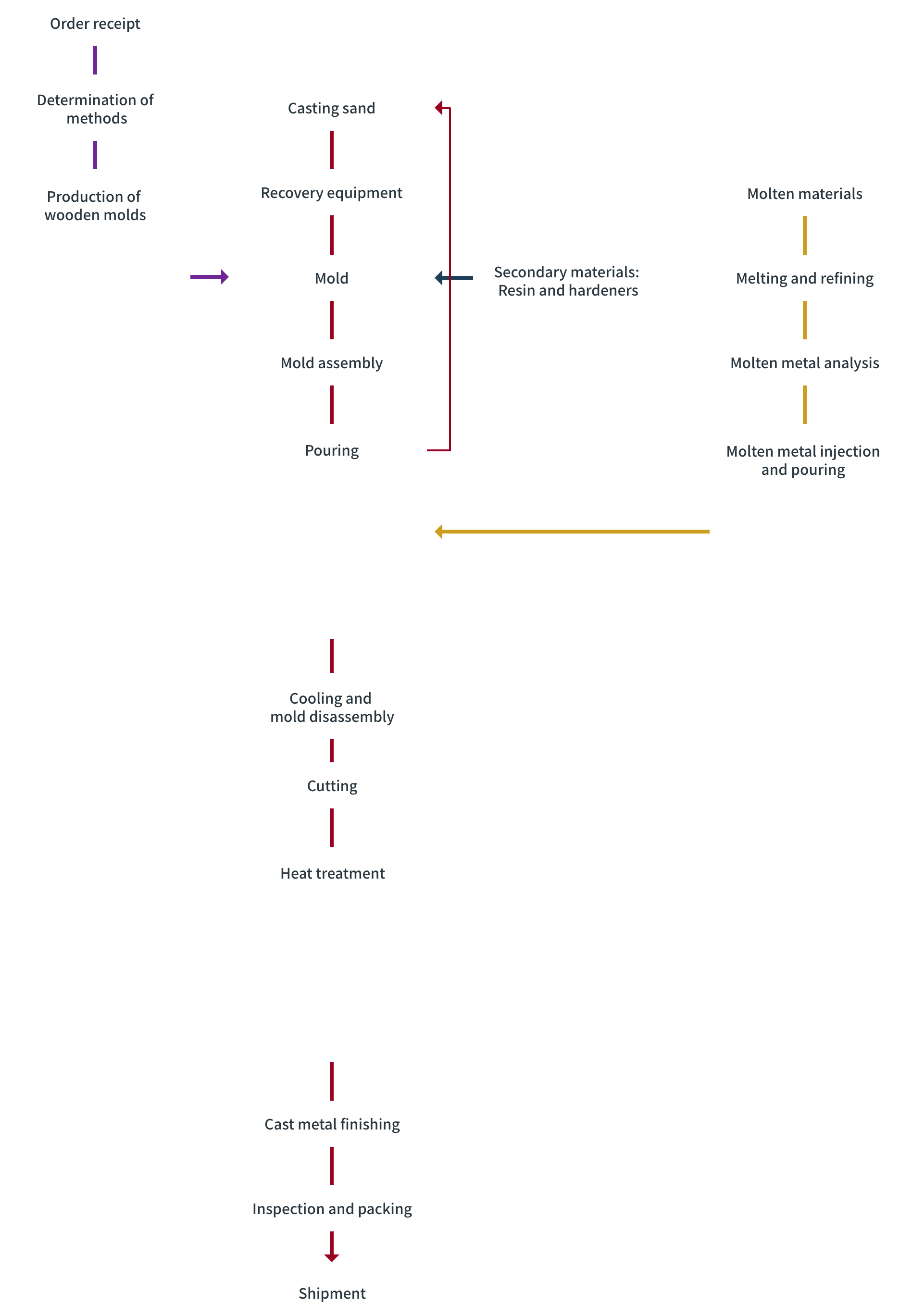

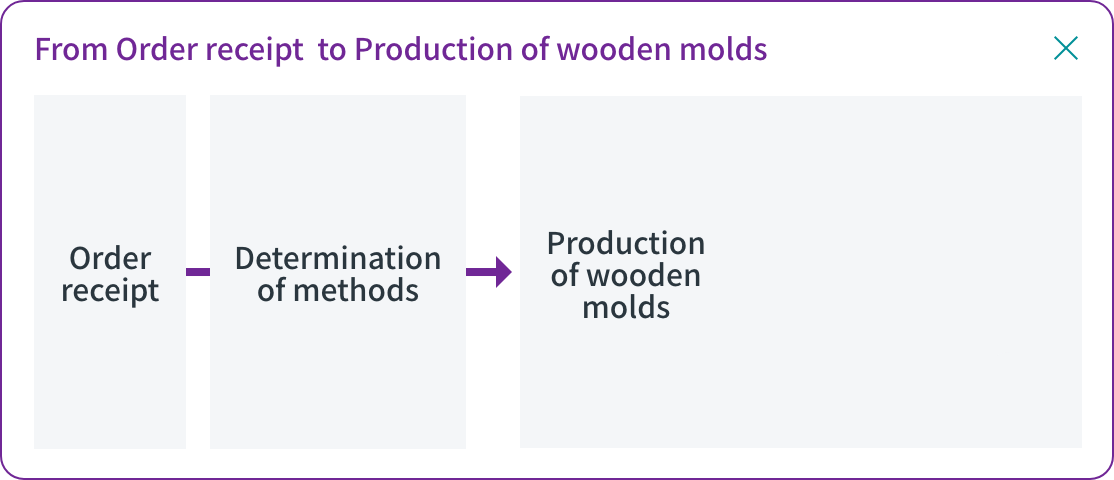

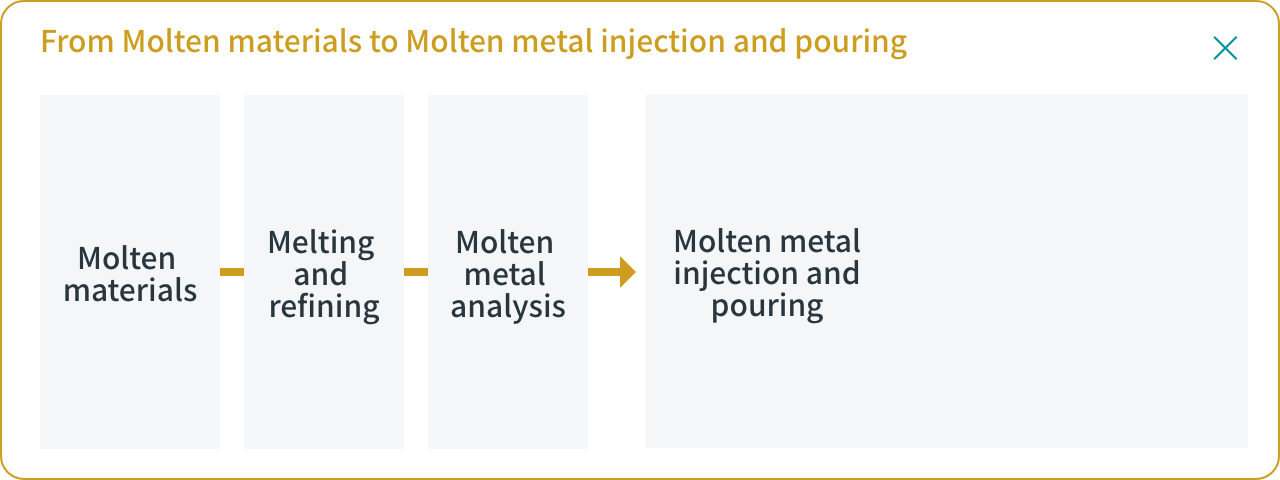

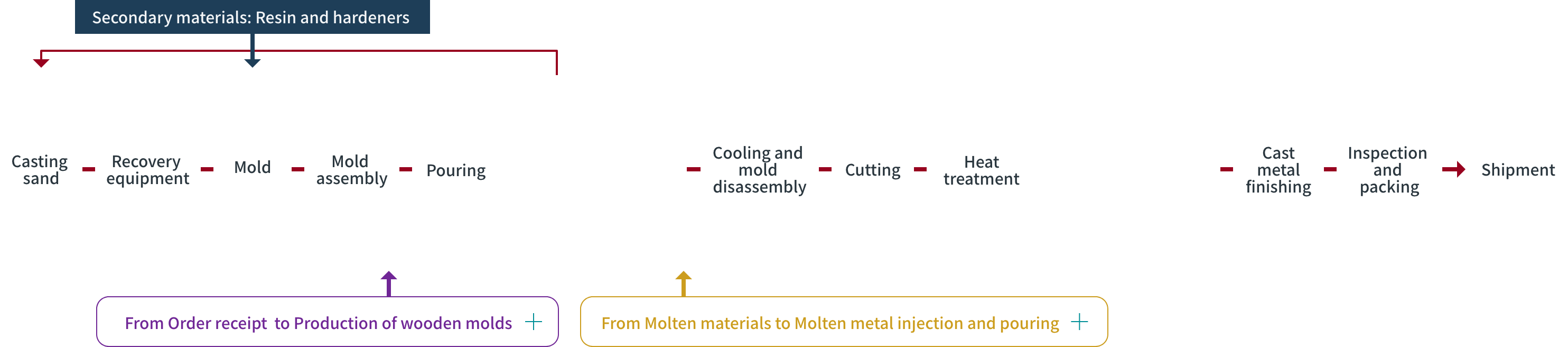

Process of producing cast steel

Watch the video

Watch the video Watch the video

Watch the video Watch the video

Watch the video