Hydrogen storage systems

Japan is a country which consumes a significant amount of energy. We have a responsibility to reduce reliance on finite resources and develop clean and renewable energy.

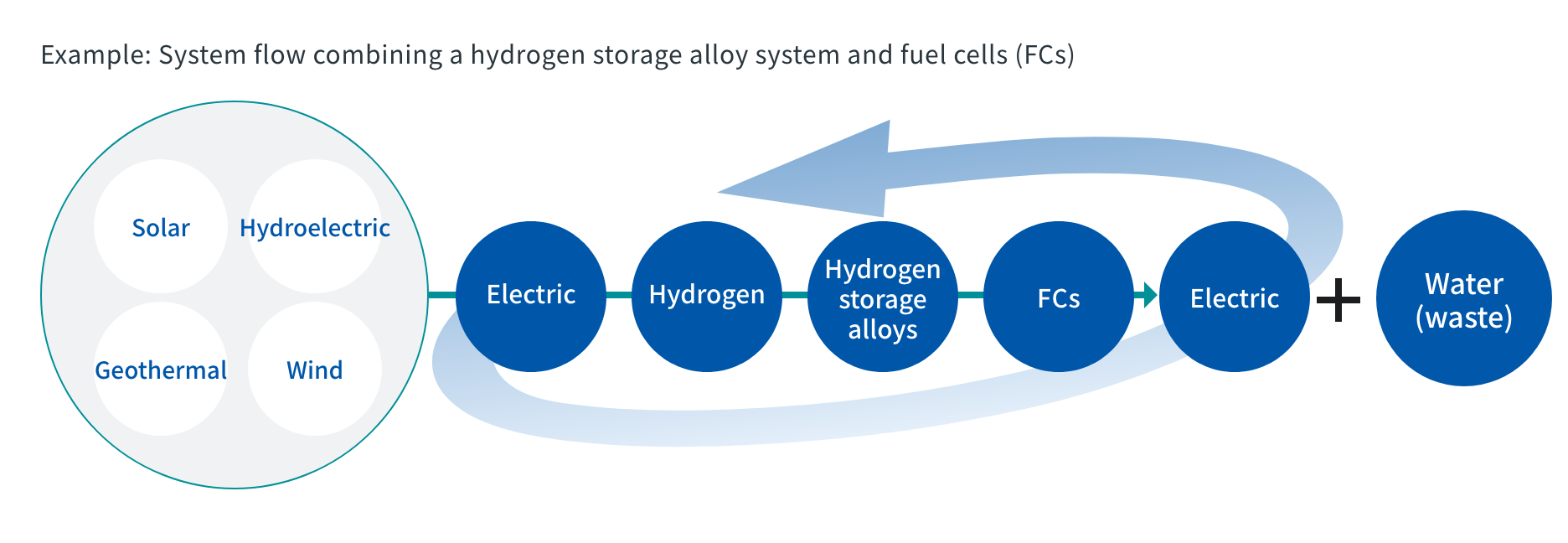

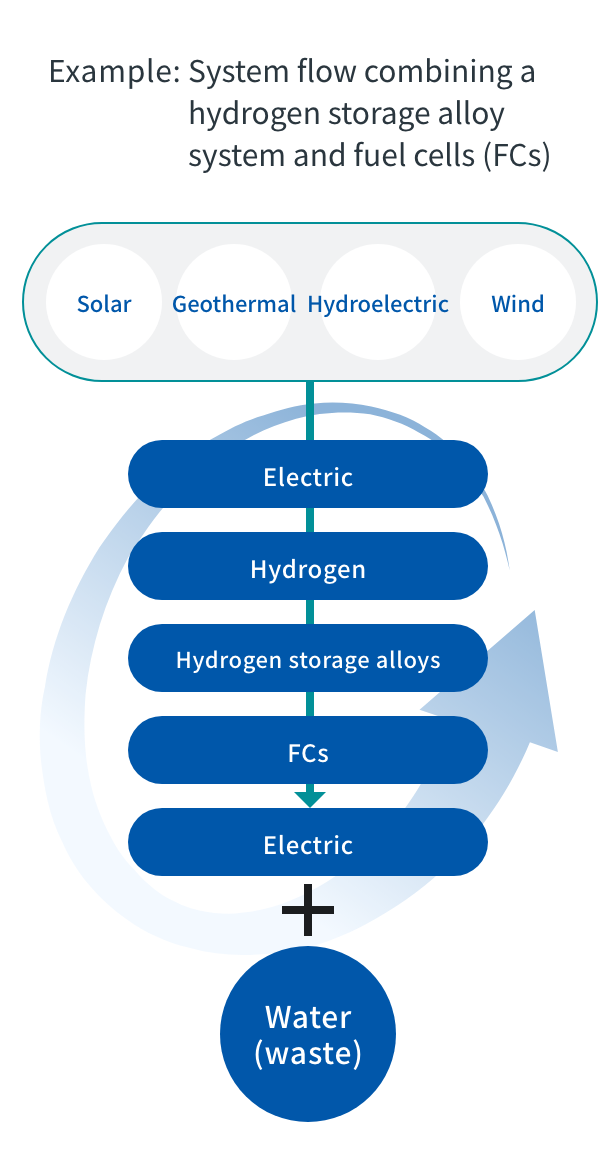

We are committed toward protecting the earth with our hydrogen storage alloy systems and the Energy Business for the next generation.

Based on the know-how we have accumulated over the years, we will propose a system that maximizes the performance of hydrogen storage alloys according to each client’s needs.

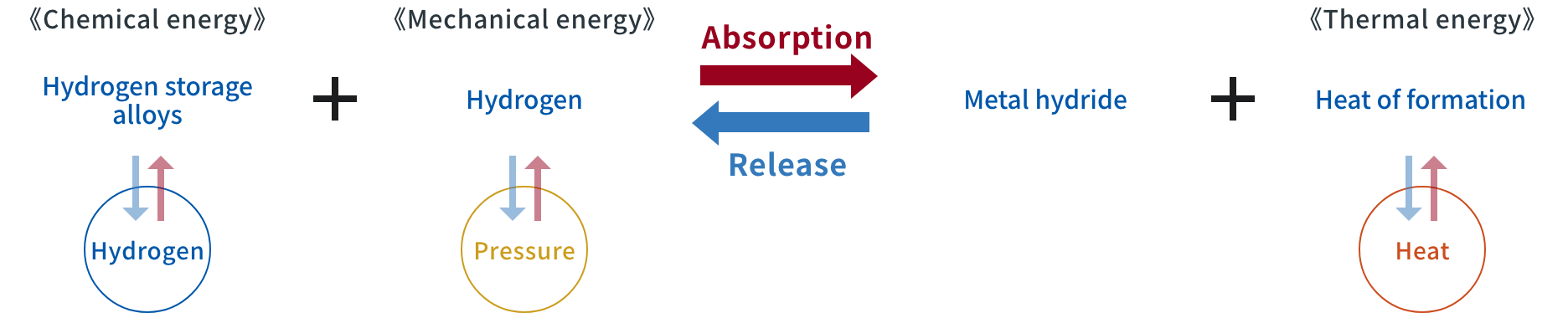

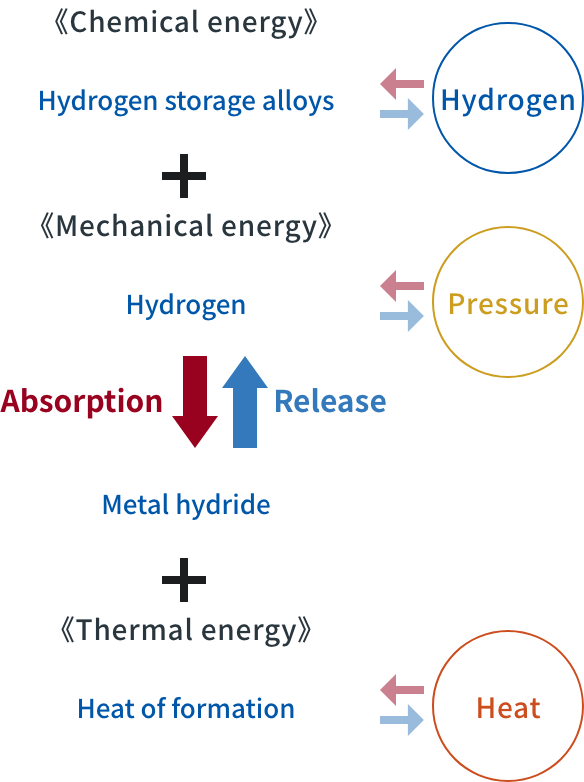

Principle of hydrogen storage alloy

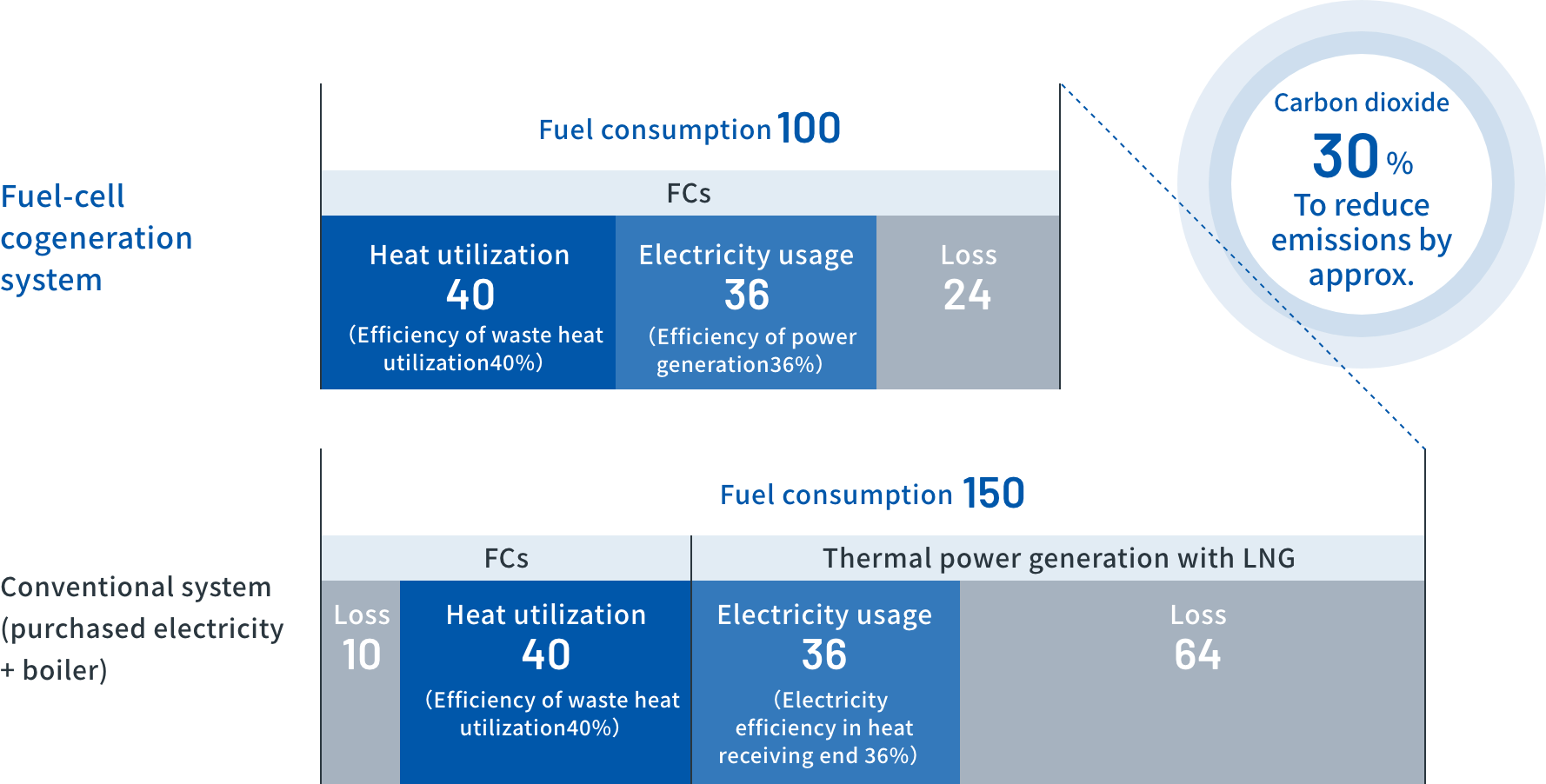

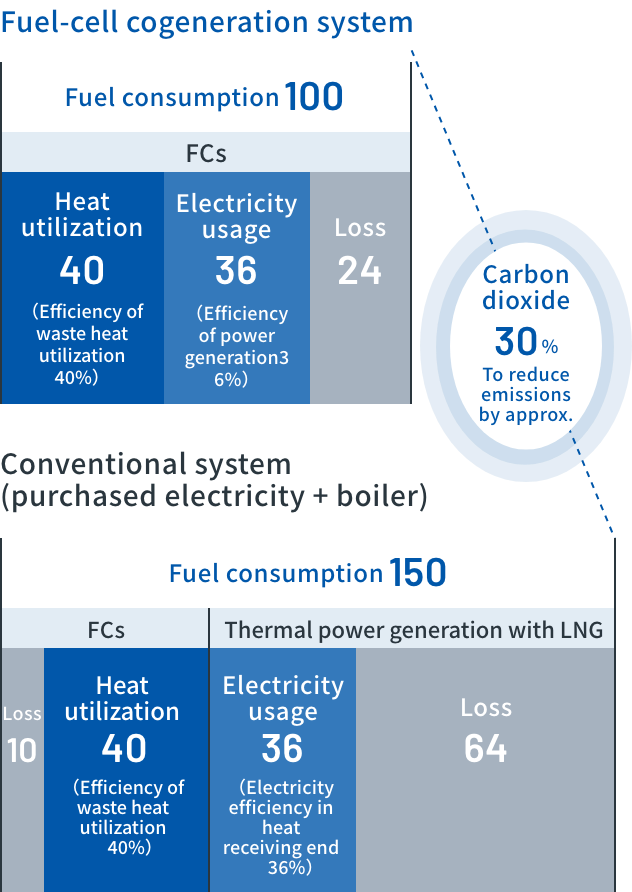

Comparison of conventional and fuel-cell cogeneration systems

The following figure represents a comparison of fuel-cell cogeneration and conventional systems.

If the same amount of energy is to be obtained at home using a fuel-cell cogeneration system, the ratio would be 150 for a conventional system while it would be 100 for a fuel-cell cogeneration system, reducing carbon dioxide emissions by up to 30%.

Taken from p. 57 of “Brief Introduction to Fuel Cells” by Nikkan Kogyo Shimbun

Product lineup

MH tank series

Safe and compact storage and supply of hydrogen, which is the future energyMH tank series by JMC

We have developed the “MH tank series,” by using hydrogen storage alloys as a safe, high-density storage method for hydrogen.

MH tanks are unique for their ability to store hydrogen safely at a low pressure, but high density.

Comparison of hydrogen storage methods

(hydrogen storage volume: 1,000 Nm3)

MH tank series

- Pressure < 1 MPa

- Occupied space: 5 m3

- Amount of heat released from hydrogen: 1,340 MJ1 (370 kWTH)

Calculated using heat of hydrogenation reaction (30 kJ/mol-H2). Removed during hydrogen filling, supplied during hydrogen release.

Conventional products

- Pressure < 1 MPa

- Occupied space: 120 m3

- Compression power: 64Wh2

Amount of power required to raise the isothermal pressure from 0.1 MPa to 1 MPa. Actual operation requires 1.5 to 3 times this value.

In-vehicle MH tank

Toward a society without CO2 emissions, vibration, or noise

The greatest advantage of FC vehicles, which use hydrogen as their energy source, is that they virtually eliminate carbon dioxide emissions.

Hydrogen storage tanks for automotive use consist of a hydrogen supply section in an alloy powder storage section and a section that provides the heat transfer medium for cooling and heating necessary during hydrogen absorption and release.

High-temperature waste heat utilization-type MH tank for automotive use

High-temperature waste heat utilization-type MH tank for automotive use In-vehicle water-cooled MH tank

In-vehicle water-cooled MH tank-

The greatest advantage of FC vehicles, which use hydrogen as their energy source, is that they virtually eliminate carbon dioxide emissions.

Hydrogen storage tanks for automotive use consist of a hydrogen supply section in an alloy powder storage section and a section that provides the heat transfer medium for cooling and heating necessary during hydrogen absorption and release.

Stationary MH tank

A day when a complete clean house is created

With the introduction of hydrogen energy to replace natural gas and electricity, the house we live in can be a completely clean house. “Making every house earth-friendly” is the mission of stationary MH tanks.

Stationary hydrogen storage tanks, including outdoor unit for air conditioners and water heaters in the home, can replace all existing electric energy in the home and support the new energy produced by hydrogen.

Stationary hydrogen storage unit

Stationary hydrogen storage unit

-

With the introduction of hydrogen energy to replace natural gas and electricity, the house we live in can be a completely clean house. “Making every house earth-friendly” is the mission of stationary MH tanks.

Stationary hydrogen storage tanks, including outdoor unit for air conditioners and water heaters in the home, can replace all existing electric energy in the home and support the new energy produced by hydrogen.

Actual cases

-

Hydrogen storage unit at Tokyo Ariake Hydrogen Station

(with a built-in hydrogen storage alloy tank)- Dimensions

- 2,200 x 1,270 x 1,750 mm

- Hydrogen absorption capacity

- 40 Nm3

- Hydrogen supply pressure

- 0.3 MPa

- Hydrogen absorption rate

- 5 Nm3/h or more

- Hydrogen release pressure

- 0.8 MPa

- Hydrogen release rate

- 20 Nm3/h

-

In-vehicle high-performance hybrid tanks

(for automotive hybrid tanks)- Internal volume

- 50.8 L

- External volume

- 66 L

- Tank weight

- 92 kg

- Hydrogen filling pressure

- 35 MPa

- Hydrogen storage volume

- 1.84 ㎏

- Storage density by weight

- 2.0 mass% by weight

- Storage density by volume

- 28 g/L

Heat pump system with hydrogen storage alloy

Comfortable, energy-saving design that releases heat in summer and captures it in winter

We have developed a heat pump system with hydrogen storage alloy to effectively use natural energy sources such as solar heat and low-grade energy sources such as factory waste heat and cooling water that were previously not utilized.

Example of utilization of the “heat pump system”

-

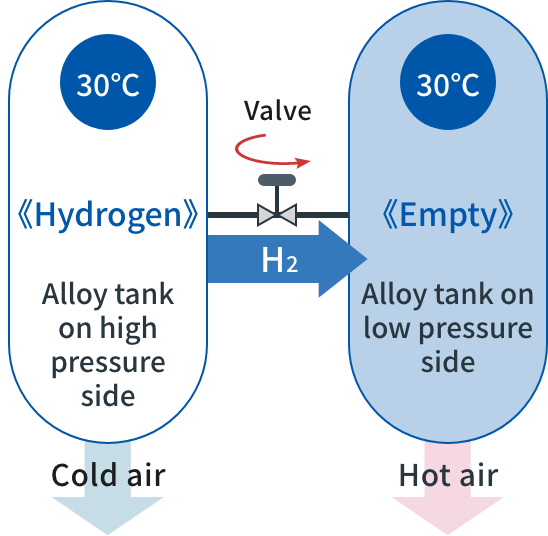

- 1

- Both alloys are maintained at 30°C. When the valve between them is opened, hydrogen is transferred from the high-pressure to low-pressure side alloy due to the equilibrium hydrogen pressure difference between them. In the high-pressure side, the alloy releases hydrogen, which causes an endothermic reaction and outputs it as cold air at 10°C.

-

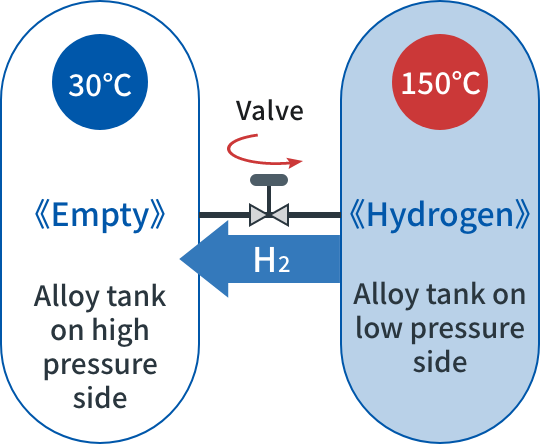

- 2

- The low-pressure side alloy is heated by a heat source of 150°C and the high-pressure side alloy is held by a heat source of 30°C. The valve between the two is opened, and hydrogen is transferred from the low-pressure side to the high-pressure side due to the equilibrium hydrogen pressure difference between the two to prepare for the next reaction.

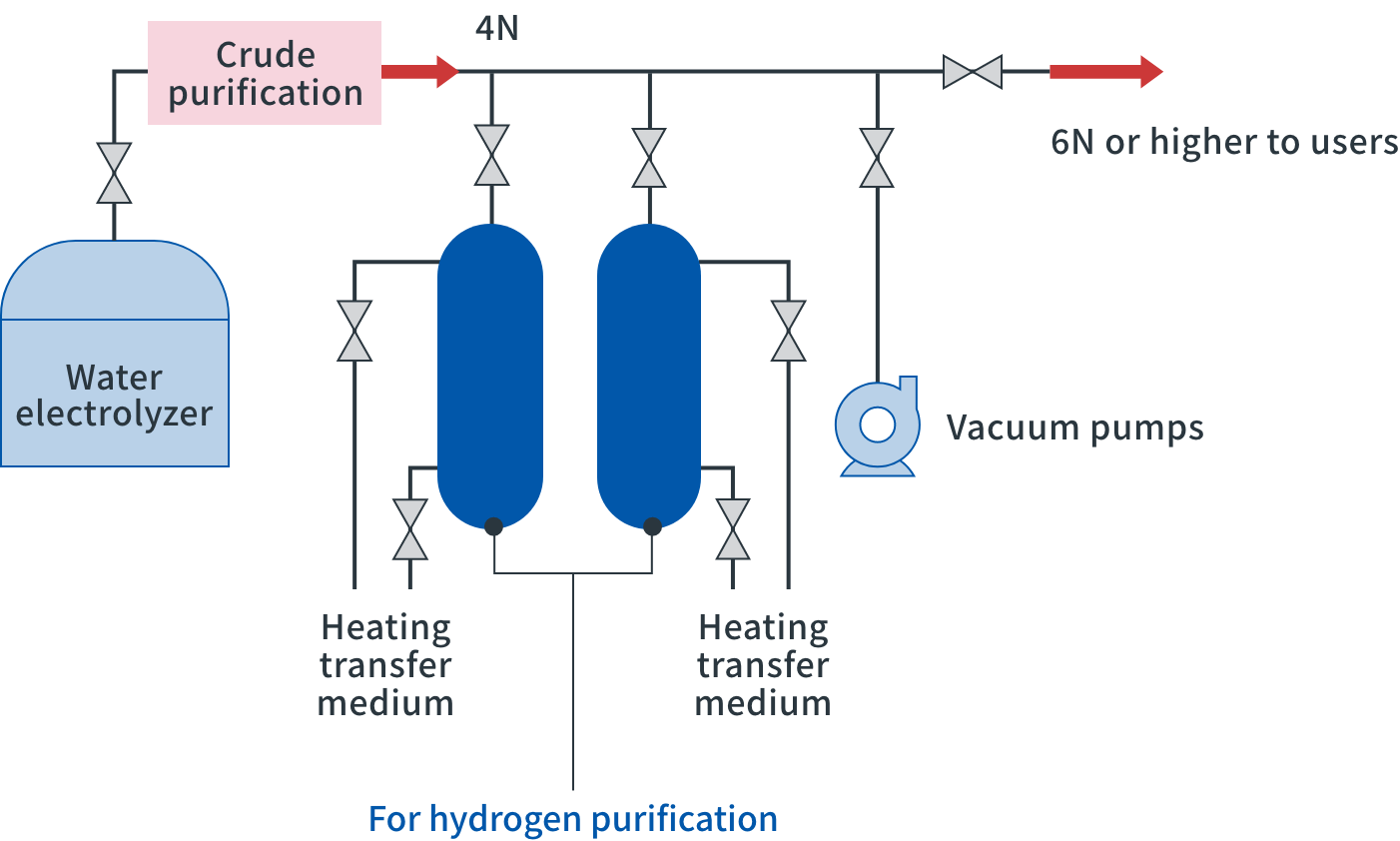

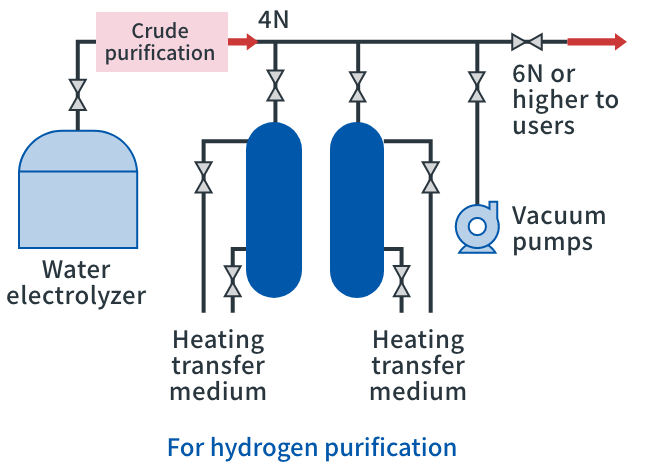

Hydrogen purification system

Delivering pure energy sources to users

Our hydrogen purification system can recover and purify low-purity hydrogen generated in water electrolyzers, etc., into high-purity hydrogen of 6N (99.9999%) or higher.

Hydrogen compressor

For quick hydrogen supply

Hydrogen compressors raise the temperature of the container in which

hydrogen is stored and increase the pressure of the hydrogen.

This allows hydrogen-filling stations to refill vehicles with hydrogen swiftly.

Hydrogen-filling station

Hydrogen-filling stationFor inquiries about hydrogen storage systems

Functional Metarials Division

Functional Materials Sales Group

Products and services related to battery materials